Diesel Truck Repair Shop Software for a More Profitable Shop

Manage your diesel truck repair shop in less time with ShopView. Higher efficiency. More profits. Less stress.

Start Free TrialManage Your Diesel Truck Repair Shop in 30%+ Less Time

ShopView simplifies and speeds up every part of your diesel truck service order management to boost your bottom line.

Effortless Service Requests

Save hours each day with fast repair request creation and management, ensuring clear and efficient customer communication.

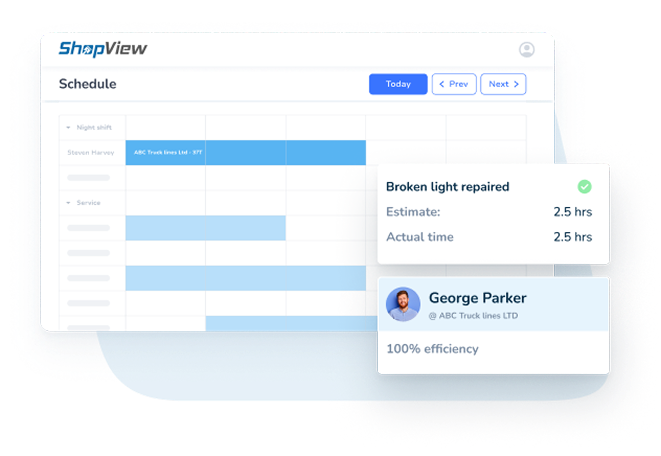

Real-Time Shop Monitoring

Track repair status, technician performance, service history, and more in real time for efficient workflow management.

Level Up Technician Productivity

A dedicated portal, zero slip time-clock, and collaborative work order tools help your techs operate at a higher level.

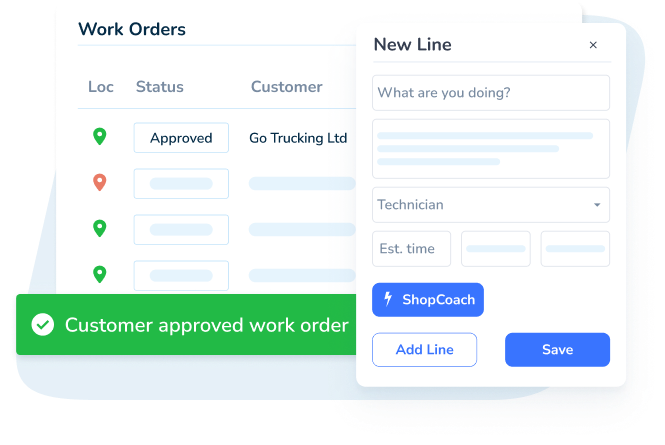

Fastest Work Order Build-Out in the Industry

Create a fully detailed work order or estimate in your diesel truck repair shop in under 2 minutes. Faster build outs mean faster profits.

Learn More About Our Work Order Features

Simplified Inventory Management

Save time and money by easily managing inventory levels, parts categorization and cycle counting.

Multi-Location Management

Keep track of parts inventory, work orders, staff, reports, and more, across multiple locations in your shop.

Automated Ordering

Save hours each day by simplifying the reordering process with automated inventory thresholds.

Comprehensive Reporting

Generate detailed reports on inventory levels, usage patterns, and reordering needs to optimize stock management.

Create Happier Customers

ShopView's diesel truck repair shop software maximizes the uptime of your customer's fleets, ensuring smooth operations and keeps your customers coming back.

Learn More About Our Uptime SolutionsFast Invoicing and Payments

Experience the simplest way to do invoicing and payments for diesel truck repair shops. Save time on processing. Get paid faster.

Quick Invoicing

Convert service orders to invoices with a few clicks and send them to customers instantly.

Accurate Billing

Invoice more accurately by viewing labor efficiencies, part margins, shop supplies, and taxes on every invoice.

Seamless Integration

Easily connect your accounting and business tools to ShopView to streamline financial operations in your shop.

Become 20%+ More Profitable with In-Depth Reporting and Analytics

Comprehensive reporting and analytics optimize your diesel truck repair shop's performance. Identify operational slippage. Profit more.

Detailed Reports

In-depth reports about shop revenue, parts inventory, technician efficiency, and preventive maintenance schedules.

Performance Boosting Analytics

Robust data analytics help you identify opportunities for improving shop performance and profitability.

Performance Tracking

Monitor key performance indicators (KPIs) to ensure your diesel shop meets its operational and financial goals.

Built By Heavy Duty Shop Owners Who Know the Grind

Our team has 20+ years of collective experience in heavy-duty repair. We built ShopView to address the real challenges we faced running our own shops - from work order chaos to billing headaches to technician productivity.

"ShopView made our shops more productive and efficient - and it will do the same for yours."

See How ShopView Helps Heavy-Duty ShopsWhy Choose ShopView?

Available on All Devices

Simple to set up and use on computers, smartphones and tablets. Your data syncs across all devices in real-time.

Seamless Integration

Connects with accounting and business systems you already use, including QuickBooks, IBS, and more.

Comprehensive Support

From onboarding to ongoing support, reach out anytime for help. We guarantee a response within 12 hours.

The Complete Guide to Diesel Truck Repair Shop Software

Why Diesel Repairs Are Tough

Diesel shops manage complex machinery powering heavy-duty trucks, buses, agricultural equipment and construction machinery. Modern diesel engines contain high-pressure fuel systems, emissions controls, turbochargers and after-treatment devices.

When breakdowns occur, they halt commerce entirely. Industry research indicates unplanned downtime costs between $448-$760 per day. Skipping routine inspections can cost fleets $760+ daily per vehicle. Labour costs average $134/hour with significant technician shortages.

Regulatory pressure from emissions rules is strict, and failing inspections removes trucks from operation. Every productive hour matters for shop profitability.

What Is Diesel Repair Shop Software?

Diesel repair shop software replaces clipboards and spreadsheets, centralizing work orders, inventory, scheduling, labour tracking, estimates, invoices, compliance records and reporting. Built-in VIN decoding and diesel-specific labour guides streamline estimates.

Key features include:

- Work order management for engines and emissions components

- Labour/time tracking by task

- Inventory management across locations

- Scheduling and dispatch with drag-and-drop calendars

- Integrated estimating and invoicing

- Compliance documentation

- Mobile access for field techs

- Reporting dashboards tracking KPIs

Where Traditional Processes Fall Short

Paper-based and spreadsheet systems create significant inefficiencies:

- Lost Billable Labour - Without task-level time tracking, approximately 1.5 hours per technician daily goes unbilled

- Inventory Issues - Real-time tracking prevents costly emergency orders and overstocking

- Scheduling Conflicts - Digital scheduling prevents bay conflicts and handles last-minute changes

- Compliance Complications - Paper records complicate audits and regulatory responses

- Cash Flow Delays - Manual invoicing delays payments and introduces billing errors

Features That Keep Diesel Shops Running

- Multi-Component Work Orders - Handle engines, transmissions, brake systems and emissions components with task assignments

- Task-Based Time Tracking - Tied to labour codes preventing lost billable minutes

- Comprehensive Inventory - Barcode scanning, reorder automation, core return tracking

- Smart Scheduling - Drag-and-drop assignment, bay/lift/tool visibility, mobile dispatch

- VIN Decoding - Diesel-specific labour guides suggesting standard hours

- Integrated Estimating/Invoicing - Accounting sync eliminating data re-entry

- Mobile Access - Field technicians with offline capability

- Compliance Documentation - Store inspections, emissions tests, warranty records

- Reports - Technician efficiency, job profitability, parts margins, PM compliance

Benefits & ROI You Can Measure

Quantifiable returns include:

- Additional Billable Hours - 1-2 per tech daily at $134/hour = hundreds weekly per tech

- Faster Turnarounds - Reducing customer downtime costs ($450-$760 daily)

- Improved Cash Flow - Same-day invoicing and fewer disputes

- Lower Inventory Costs - Automation and real-time tracking

- Stronger Compliance - Supporting audits and customer trust

- Higher Staff Satisfaction - Reducing turnover

The global fleet management software market projects growth from $27.55B (2024) to $116.56B (2032) - 19.76% CAGR with North America holding 40% market share.

Real Stories from the Shop Floor

Foothills Group achieved 100% technician productivity, saved over 10 hours weekly at the service desk, and gained approximately $15,000 monthly revenue.

Haylock Truck & Trailer cut turnaround times and improved fleet customer communication moving from paper processes.

SS Auto Repair reduced billing errors and freed staff for profitable tasks.

Industry research shows digital tool adoption accelerating as fleets expect service partners offering digital communication, data-backed estimates, and minimal downtime.

Choosing the Right Diesel Software

Evaluation checklist:

- Diesel Focus - Handles diesel engines, emissions systems, heavy-duty components

- Ease of Use - Intuitive interface for service writers, parts managers, technicians

- Comprehensive Modules - Work orders, time tracking, inventory, scheduling, estimating, invoicing, compliance, reporting in unified system

- Mobile Support - Field techs access on phones/tablets, offline capability

- Integrations - QuickBooks, suppliers, payment processors, VIN decoders, telematics

- Pricing - Transparent, predictable, no hidden fees, flexible contracts

- Scalability and Support - Vendor grows with your business, quality support, heavy-duty expertise

How to Roll It Out

- Document Current Processes - From intake to invoice, identifying delays/errors

- Research and Demo - 2-3 vendors using real scenarios

- Clean Data - Gather customers, unit numbers, VINs, parts catalog, labour codes

- Run Pilot - One tech/bay for 2 weeks maintaining backup processes

- Train Small Groups - Specific tasks with cheat sheets

- Gradual Rollout - Adding technicians/modules progressively

- Monitor with Reports - Tracking unbilled hours, parts margins, invoice turnaround

- Communicate - With fleet clients about digital estimates/updates

- Calculate ROI - After months comparing key metrics to baseline

Looking Ahead: Trends and Future Proofing

Diesel technology continues evolving with tightening emissions rules, standard telematics/IoT sensors, and emerging electric trucks.

Modern software integrates diagnostic data and telematics alerts into work orders, supports new powertrain types, and offers predictive maintenance based on mileage/sensor readings.

AI increasingly suggests repairs before failures and optimizes scheduling from historical data. Fleets expanding technology budgets and adopting maintenance platforms rapidly.

Independent and mid-sized repair shops investing now gain competitive positioning for fleet contracts, skilled technician recruitment, and market competition.

Conclusion: A Better Way to Run Your Diesel Shop

Unplanned downtime and missed labour hours are expensive. Paper processes and generic software cannot manage complex diesel repairs effectively.

Purpose-built diesel repair software integrates work orders, parts, labour, scheduling, compliance and billing in unified systems. Shops using these tools recover hours, improve parts control, reduce invoice turnaround, and increase revenue while supporting technician satisfaction.

Industry movement accelerates - regulations tighten, technology adoption increases, fleets demand digital service. Investing in proper software positions shops to maintain pace, eliminate clipboards, eliminate labour guessing, and provide transparency customers demand.

Ready to Increase Your Shop's Revenue by 20%+?

Join thousands of heavy-duty repair shops that trust ShopView to manage their operations profitably.