Fleet Maintenance Management Software

ShopView's fleet maintenance management software empowers fleet managers to optimize efficiency, improve relationship with drivers, and extend asset longevity.

Start Free TrialMaximize Fleet Uptime

Optimize Efficiency

Streamline operations, reducing administrative burdens and maximizing productivity through automated and optimized processes.

Seamless Communication

Maintain real-time updates and effective coordination to enhance fleet performance and responsiveness.

Extend Asset Longevity

Proactive maintenance tracking and comprehensive service orders prevent costly breakdowns and ensure optimal performance.

Proactive Scheduling

Stay ahead of preventive maintenance with ShopView. Our software tracks mileage and engine hours, ensuring you always know when regular maintenance and inspections are due.

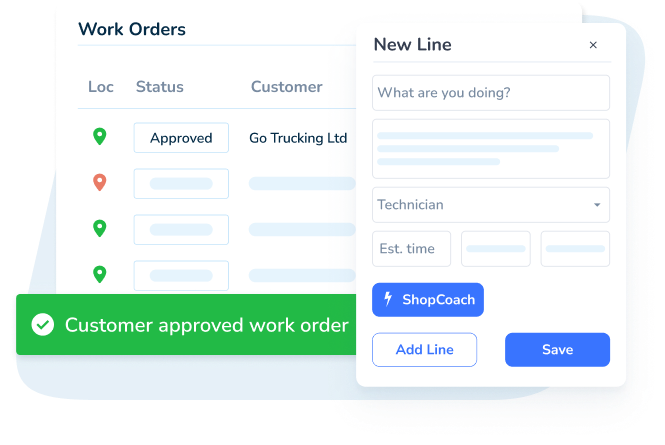

Learn More About Our Work Order Features

Inventory and Procurement Management

Track Usage Patterns

Monitor parts usage to understand demand and ensure optimal inventory levels.

Forecast Needs

Use data-driven insights to predict future inventory requirements, preventing stockouts and overstock.

Reduce Rush Order Expenses

Maintain necessary parts availability, minimizing costly last-minute orders and avoiding downtime.

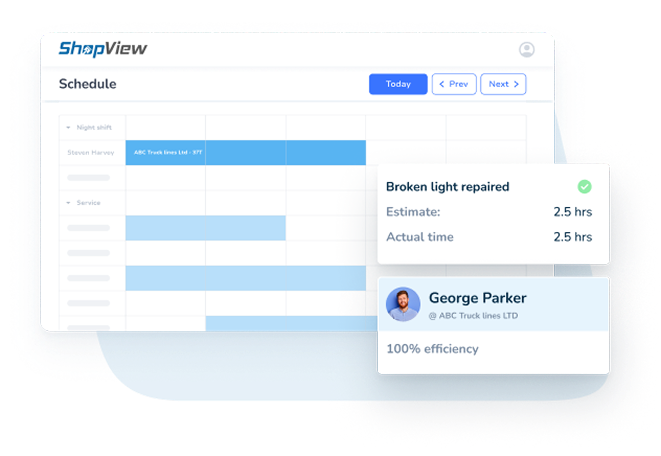

Boost Technician Efficiency by 20%

Speeds up workflows allowing technicians to spend more time on fleet maintenance and less on administrative tasks through automated scheduling and real-time updates.

Learn More About Our Uptime SolutionsStreamline Fleet Maintenance Reporting

Total Cost of Ownership

Easily calculate the comprehensive costs associated with your fleet to make informed financial decisions.

Run Batch Reports

Generate comprehensive reports efficiently to analyze various aspects of your fleet operations.

Analyze Technician Statistics

Evaluate productivity and efficiency of your technicians with detailed statistical insights.

Improve Fleet Safety and Compliance

Automated Regulatory Compliance

Automatically adhere to safety regulations, reducing risk of fines and accidents, lowering insurance premiums.

Proactive Maintenance Protocols

Schedule and track preventive maintenance to avoid unexpected breakdowns, ensuring continuous fleet operation.

Detailed Maintenance Reports

Generate comprehensive reports to monitor maintenance activities, ensuring vehicles meet safety standards.

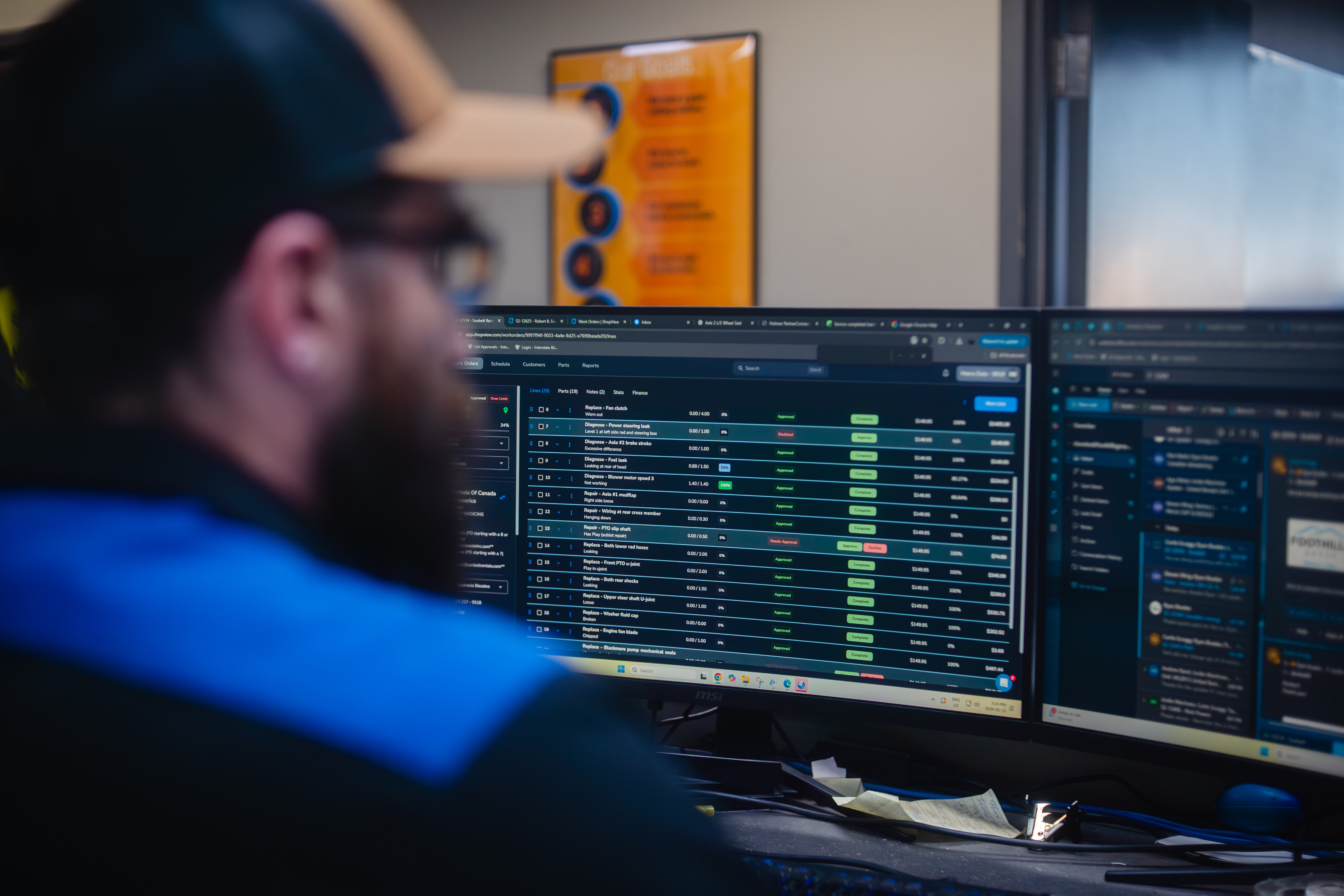

Built By Heavy Duty Shop Owners Who Know the Grind

Our team has 20+ years of collective experience in heavy-duty repair. We built ShopView to address the real challenges we faced running our own shops - from work order chaos to billing headaches to technician productivity.

"ShopView made our shops more productive and efficient - and it will do the same for yours."

See How ShopView Helps Heavy-Duty ShopsWhy Choose ShopView?

Available on All Devices

Simple to set up and use on computers, smartphones and tablets. Your data syncs across all devices in real-time.

Seamless Integration

Connects with accounting and business systems you already use, including QuickBooks, IBS, and more.

Comprehensive Support

From onboarding to ongoing support, reach out anytime for help. We guarantee a response within 12 hours.

Fleet Maintenance Management Software: Keep Your Fleet on the Road

Introduction: Why Fleet Maintenance Matters More Than Ever

If you run a fleet of trucks, trailers or heavy equipment, you already know that downtime is expensive. When a tractor or excavator is parked instead of working, it isn't hauling freight or digging trenches - it's burning cash.

Industry analysts estimate that unplanned downtime for a heavy-duty vehicle costs around $448 to $760 per day. Skipping preventive maintenance and inspections can raise those costs to $760 per vehicle per day.

Fleets are also more complex today than they were a decade ago. You might have a mix of sleepers, day cabs, dump trucks, trailers with refrigeration units, backhoes, bulldozers and generators. Some vehicles run on diesel, others on CNG or electric drivetrains. Regulations are tightening around emissions and driver safety.

What Is Fleet Maintenance Management Software?

Fleet maintenance management software is a digital platform that centralizes all the tasks involved in keeping your vehicles in top condition. It brings together:

- Asset Registry - Detailed database of every unit with VINs, purchase dates, warranty details and maintenance history

- Preventive Maintenance Schedules - Customizable plans triggered by mileage, engine hours or calendar intervals

- Work Order Management - Create, assign and track work orders with labour tasks, parts, notes and photos

- Inventory and Purchasing - Manage parts stock, set reorder points, generate purchase orders

- Labour and Time Tracking - Record technician hours by task and feed data into payroll

- Compliance Documentation - Store inspections, DVIRs, emissions tests, permits and certifications

- Reporting and Analytics - Dashboards on uptime, cost per mile, technician productivity

- Integrations - Connect with telematics, fuel cards, accounting software

Pain Points in Fleet Maintenance

Unplanned Downtime - Costs far more than preventive maintenance. Sudden breakdowns trigger towing fees, emergency labour rates and lost revenue ($450-$760 per day).

Complex Scheduling - Keeping track of hundreds of different service intervals across multiple assets and locations is nearly impossible with spreadsheets.

Data Silos - Many fleets cobble together separate systems for parts inventory, work orders, accounting and compliance.

Field Service Gaps - When repairs happen on jobsites or roadside, technicians jot down notes on paper, leading to missing labour time and unbilled parts.

Regulatory Compliance - Mixed fleets need DOT, OSHA, EPA and industry-specific compliance documentation.

Key Features to Look For

- Robust Asset Registry - Support multiple asset types with VINs, engine numbers, warranty status and custom fields

- Flexible PM Scheduling - Templates or custom intervals, automatic work order generation

- Quick Work Orders - Enter unit number, pick tasks, assign technician, set due date

- Parts Management - Real-time stock levels, barcode scanning, automated reorder alerts, core tracking

- Accurate Labour Capture - Time clocks integrated with work orders for real-time visibility

- Compliance Support - Electronic DVIRs, DOT inspection scheduling, emissions test storage, OSHA safety checks

- Real-Time Dashboards - Average downtime, PM compliance rate, cost per mile, parts usage, technician efficiency

- Integration Capabilities - Telematics, fuel programs, accounting, parts suppliers, payment processors

Benefits & Evidence

Reduced Breakdowns - Moving from reactive to preventive maintenance can reduce unplanned downtime by up to 20%. With downtime costs of $450-$760 daily, savings add up fast.

Complete Visibility - See which assets cause most downtime, which technicians are most productive, where parts budgets go.

Better Planning - Plan jobs during off-peak times, balance workloads, avoid overloading certain shops.

Extended Asset Life - Consistent maintenance leads to higher resale prices and well-documented service histories.

Time Savings - Automating work order creation, parts ordering and data entry frees managers for higher-value tasks.

Scalability - Add units, locations and users without starting over. The fleet management market is projected to grow from $27.55B (2024) to $116.56B (2032).

Case Studies & Testimonials

Foothills Group - Transitioned from multiple disconnected systems to a unified platform: 100% technician productivity, over ten hours saved per week at the service desk, and an additional $15,000 per month in revenue.

Mid-Size Regional Trucking Company - 20% reduction in emergency repairs and significant decrease in parts pilferage.

Construction Equipment Operator - Real-time tracking of parts across job sites allowed better use of existing inventory.

Smaller independent repair shops benefited by digitizing work orders and scheduling to improve turnaround time and attract new fleet customers who valued transparency.

How to Evaluate & Implement Fleet Maintenance Software

Evaluation Criteria:

- Does it support heavy-duty trucks, trailers, construction equipment?

- Is it comprehensive - asset registry, PM, work orders, inventory, labour tracking, compliance, reporting, integrations?

- Can it scale with your fleet size?

- Is the interface intuitive for busy managers and techs?

- Do techs have mobile access with offline capability?

- Does it integrate with telematics, fuel programs, accounting, suppliers?

Implementation Steps:

- Define problems to solve and set measurable targets

- Document current work order, PM, procurement, tracking and billing processes

- Compile asset lists, schedules, parts catalogs, vendors, contacts

- Pilot with a subset of vehicles or single shop, keeping old system in parallel

- Provide bite-sized training focused on daily tasks

- Track metrics during pilot: downtime, parts usage, labour capture, invoice turnaround

- Expand in phases, informing all stakeholders about the new system

- Compare KPIs to baseline after a full quarter

Conclusion: Keeping Your Fleet on the Road

In a world where uptime is money, managing a fleet with paper checklists and disconnected software is a recipe for lost revenue and compliance headaches.

Purpose-built fleet maintenance software centralizes assets, schedules, work orders, parts, labour and compliance records in one place. It helps you cut unplanned downtime, control parts costs, improve labour productivity and gain the visibility needed for informed decisions.

Preventive maintenance can reduce downtime days by 20% and adopting modern maintenance tools is a growing trend. Shops and fleets that have made the switch are seeing tangible results - higher technician productivity, more billable hours, reduced emergency repairs and stronger customer satisfaction.

Don't let downtime drain your profits. Take control of your fleet's health and keep your vehicles rolling.

Ready to Increase Your Shop's Revenue by 20%+?

Join thousands of heavy-duty repair shops that trust ShopView to manage their operations profitably.