Heavy-Duty Truck Labor Time Guide, Smarter, Faster with AI

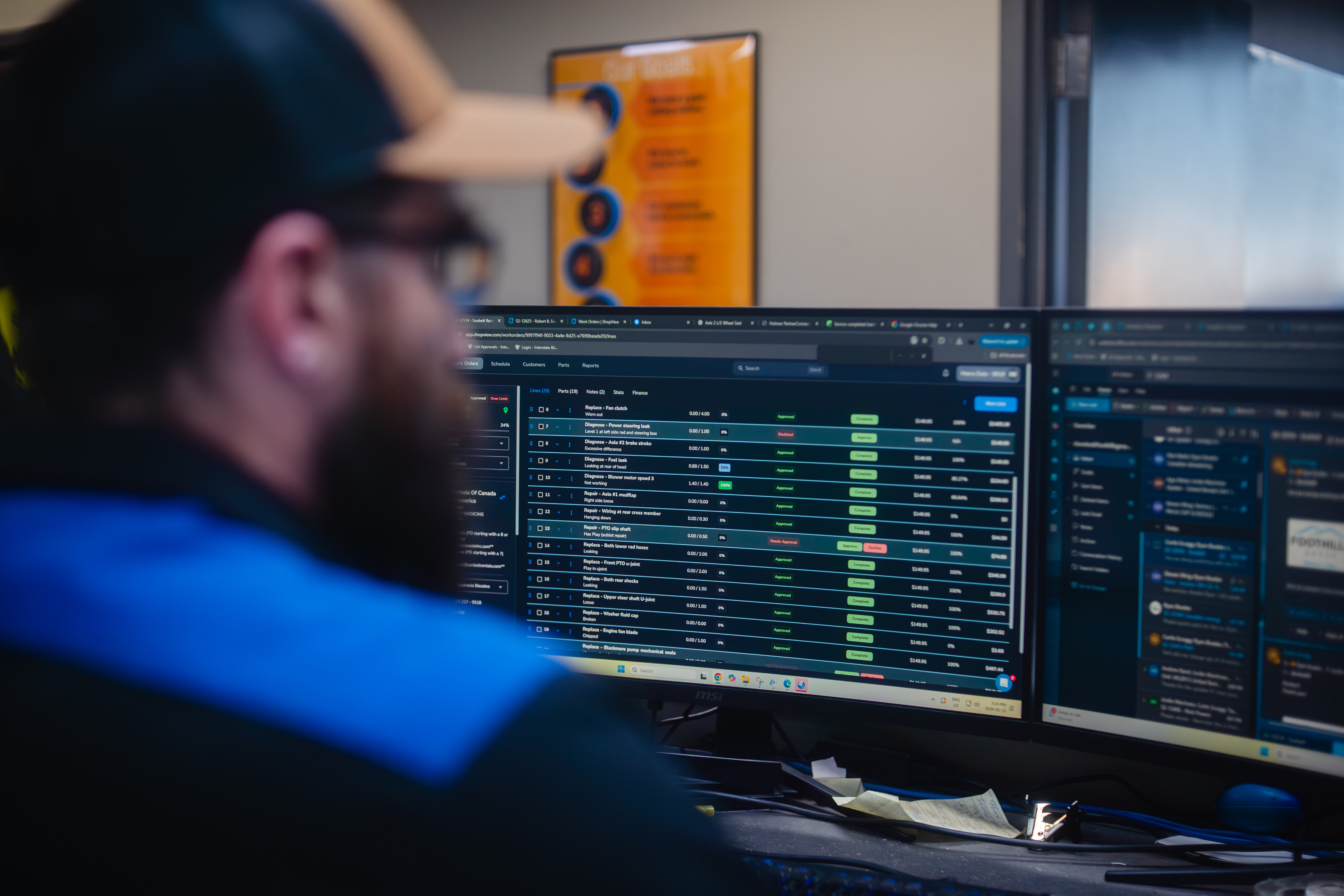

Say goodbye to static labor guides and manual lookups. ShopCoach AI delivers VIN-specific labor times and real-time estimates in seconds - all built directly into ShopView.

The Problem with Traditional Labor Time Estimating

Manual Lookups Delay Job Approvals

Manual lookups delay job approvals and slow down your entire workflow.

Outdated Averages

Estimates are based on outdated averages that don't reflect actual job complexity.

Missed Lines = Missed Revenue

Missed lines = missed revenue. Every forgotten item costs your shop money.

You Don't Need a Labor Time Guide, You Need This

Type a Prompt

"2018 Peterbilt needs turbo replacement"

ShopCoach AI Instantly Builds

VIN-based labor time, parts suggestions from inventory, pre-written tech story, real-time pricing and markup.

Review and Approve

Convert to a complete work order in seconds.

Why ShopCoach AI Outperforms Traditional Labor Guides

| Feature | ShopCoach AI | Traditional Guides |

|---|---|---|

| Estimate Speed | Instant, AI-generated | Manual and slow |

| Accuracy | VIN-specific labor times, real-time | Based on old averages |

| Workflow Integration | Built into ShopView | Not connected |

| Revenue Recovery | Flags missed/declined lines | None |

Key Benefits of ShopCoach AI for Labor Time Estimation

Work Orders in Seconds

Type one sentence. Get a complete estimate, instantly.

More Revenue Per Job

Never miss a line or a billed hour again.

Accurate by Design

VIN data + real-time shop history = smart estimates every time.

Less Admin, More Repairs

No more flat-rate flipping or retyping work orders.

Seamless Integration with ShopView

VIN Decoding + Service History

Inventory & Parts Catalog Access

QuickBooks Integration

Cloud-Based + Mobile-Friendly

Use It on Day One, No Training Required

Foothills Group: From Garage Startup to $20M+ Revenue

Extra Revenue per Month

Saved per Tech per Day

Faster Work Order Creation

"ShopView allows us to focus on getting the job done. As a technician, I have the freedom to build jobs and switch between tasks without needing help from admin."

— Heather F.

Ready to Replace Your Labor Time Guide?

Start your free trial today and see how ShopCoach AI transforms your estimating process.

Start Free TrialA Practical Guide to Heavy-Duty Truck Labor Time Guides

Introduction

When you quote a diesel engine overhaul or a trailer brake job, you're not just scribbling numbers on a scratch pad - you're betting your margins on how long the job will take. Under-estimate the hours and you eat the cost; over-estimate and your customer balks.

In heavy-duty repair, accurate labor times are critical to profitability. Industry reports estimate that an out-of-service heavy vehicle can cost between $448 and $760 per day in lost revenue.

Why Accurate Labor Times Matter

Heavy-duty repairs are complex. A straightforward brake job on a medium-duty truck might take two hours, but if rusted bolts or aftermarket components enter the mix, time doubles.

Diesel engines, transmissions and emissions systems vary widely by make, model and year. If you quote labor based on generic averages or old manuals, you'll likely undercharge on difficult jobs and overcharge on simple ones.

Misquoting labor also cascades into scheduling. If you plan two hours for a clutch job that takes four, you'll run into bottlenecks, delay other work and risk overtime costs.

Traditional vs. Modern Solutions

For decades, shops have relied on printed manuals or PDF labor guides. These have serious drawbacks:

- Out-of-Date Information - Printed guides may not include the latest models or technology

- Generic Averages - Don't reflect variables like four-wheel drive, PTO attachments, or corrosion

- Manual Lookup - Flipping through pages takes time and causes errors

- No Integration - Paper guides don't connect to your shop management software

Modern labor time guides solve these problems by integrating directly into your repair software and tailoring times to the exact vehicle.

What Is a Labor Time Guide?

A labor time guide is a database that provides estimated labor hours for specific repair operations. For heavy-duty trucks, a modern guide:

- Decodes VINs - Pulls make, model, engine type, transmission and optional equipment

- Generates Operation Codes - Labor hours specific to that vehicle and engine

- Integrates Parts Suggestions - Parts, pricing and core charges from vendor data

- Provides Repair Stories - Step-by-step instructions and torque specs

- Updates Continuously - Cloud-based guides update with new models and bulletins

- Integrates with Work Orders - Labor times push directly into your shop system

Challenges with Manual Guides

Out-of-Date Times - Old manuals can't keep pace with rapidly changing technology. Using outdated data results in underbilling and scheduling chaos.

Time Wasted Searching - Your service writer shouldn't spend five minutes flipping pages to find a code. Digital systems reduce lookup time to seconds.

No Modification Accounting - Aftermarket lift kits, PTOs, and custom upfits add hours that manual guides ignore.

No Integration - Manual guides require rekeying labor hours, introducing errors.

Features of Digital Labor Guides

- VIN-Specific Labor Times - Tailored to exact vehicle configuration and engine architecture

- Parts Integration - Suggestions and pricing based on vendor catalogs with core charges

- Pre-Written Repair Stories - Step-by-step instructions, tools, torque specs, diagrams

- Continuous Updates - Cloud-based updates with access from any device

- Work Order Integration - Labor hours flow directly into estimates and invoices

- AI Enhancements - Learn from your shop's actual labor times

Real-World Results

Shop A - 10-Bay Diesel Repair: Increased labor revenue by 12% on complex jobs, reduced estimate time by 60%, fewer customer disputes.

Shop B - Medium-Duty Service Center: Added $9,000 per month in recovered labor, reduced turnaround time, trained new service writers in half the time.

Shop C - Trailer Repair Facility: Customer complaints about surprise hours dropped 70%, better scheduling reduced overtime, improved customer satisfaction and repeat business.

How to Evaluate and Implement

Evaluation Criteria:

- Accuracy and Coverage - Does it cover your makes, models and years?

- Update Frequency - Monthly or quarterly updates ensure current data

- Ease of Use - VIN entry to operation selection should be quick

- Integration - Seamless connection with your existing shop software

- Pricing Model - Subscription, per user, or per lookup

- Support and Training - Access to training materials and responsive support

- Customizability - Adjust labor times based on your shop's experience

Implementation Steps: Inventory existing processes, select a tool, train staff, start with common repairs, review and refine.

Conclusion: Get Paid for Every Minute

Old-fashioned labor guides served the industry for decades, but they can't keep up with modern heavy-duty trucks and equipment. The cost of downtime - estimated at $448-$760 per day for each truck - makes precise scheduling and billing more important than ever.

Generic times and guesswork lead to underbilled jobs, scheduling chaos and frustrated customers. In contrast, digital labor guides with VIN decoding, parts integration and continuous updates deliver accurate estimates, improve customer trust and boost revenue.

Adopting a modern labor time guide is an investment in profitability and efficiency. By quoting and billing accurately, you get paid for every minute your technicians work.

Ready to Increase Your Shop's Revenue by 20%+?

Join thousands of heavy-duty repair shops that trust ShopView to manage their operations profitably.