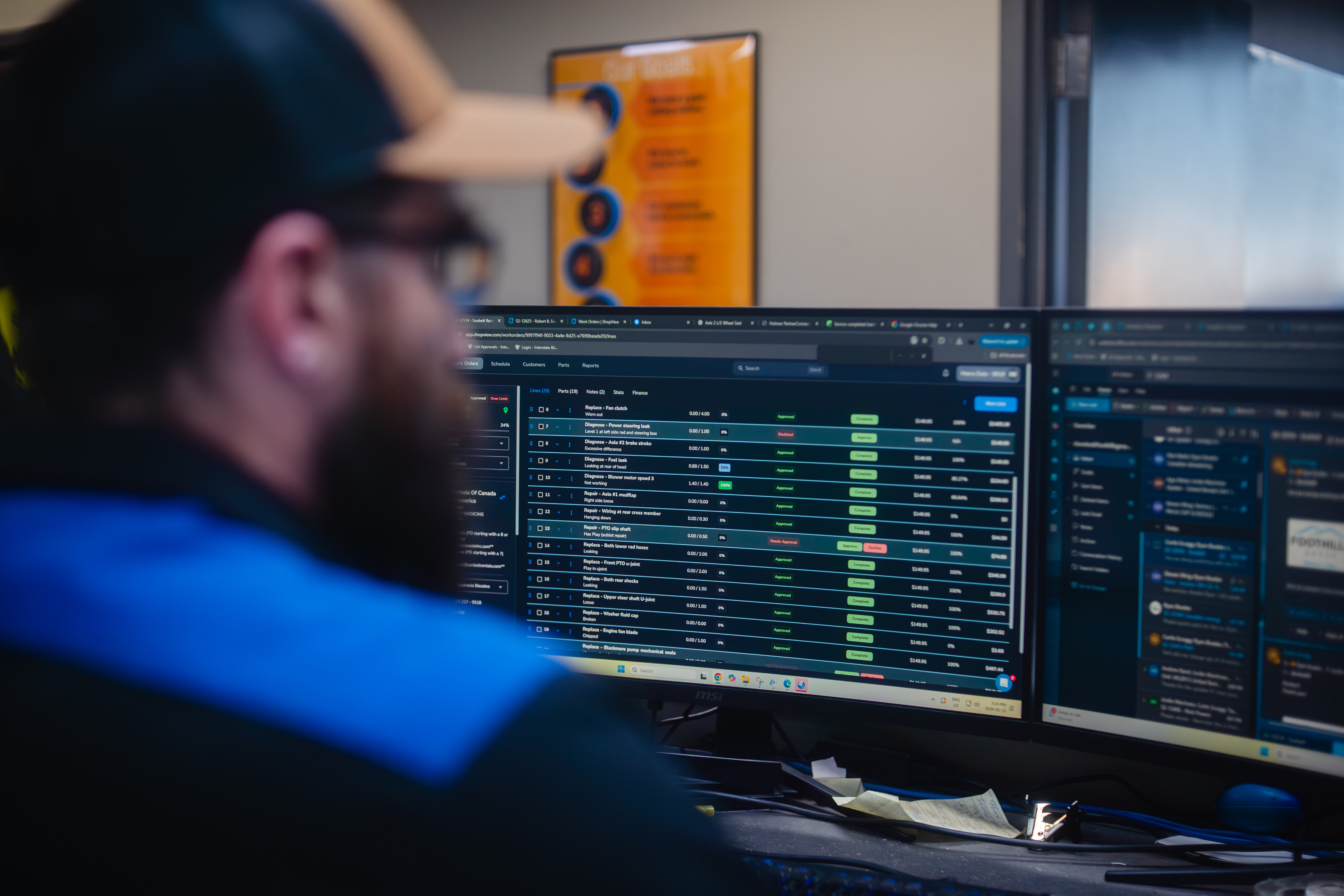

Truck and Trailer Repair Software That Keeps Your Shop Profitable

Run your truck and trailer repair business more efficiently with ShopView, the fastest, easiest way to manage service orders, inventory, invoicing, and team productivity.

Start Free TrialGet Jobs Done Faster with Simplified Service Order Management

From axle work to reefer units, ShopView streamlines the entire repair process.

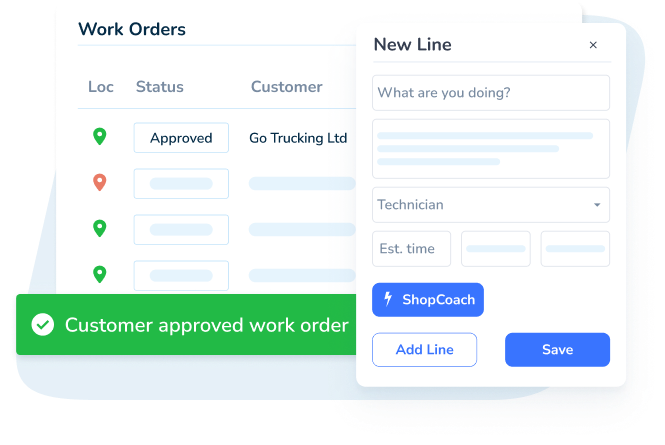

Faster Service Order Intake

Create detailed repair orders in seconds with templates, saved services, and instant access to past job history.

Track Progress in Real Time

Live visibility into open jobs and repair statuses across bays.

Streamlined Communication

Keeps techs, front office, and customers aligned without paperwork.

Fastest Work Order Build-Out in the Industry

Build a fully loaded, accurate work order or estimate in under 2 minutes.

Learn More About Our Work Order Features

Trailer-Ready Inventory Management

Live Parts Tracking

Real-time visibility across shop and mobile units.

Automated Reordering

Set thresholds to prevent stockouts.

Detailed Inventory Reporting

Identifies fast-moving parts and reduces overstock.

Keep Trucks & Trailers Road-Ready with Preventive Maintenance

Stay on top of DOT compliance and proactive service scheduling to keep your customers' fleets on the road.

Learn More About Our Uptime SolutionsSimplify Invoicing and Get Paid Faster

Quick Invoicing

Click to convert work orders into invoices instantly.

Full Financial Clarity

View margins and tech efficiency on every invoice.

Seamless Integration

Connect with accounting software like QuickBooks.

Boost Profits with Data-Driven Shop Management

Revenue Reporting

Comprehensive reports on shop revenue and performance.

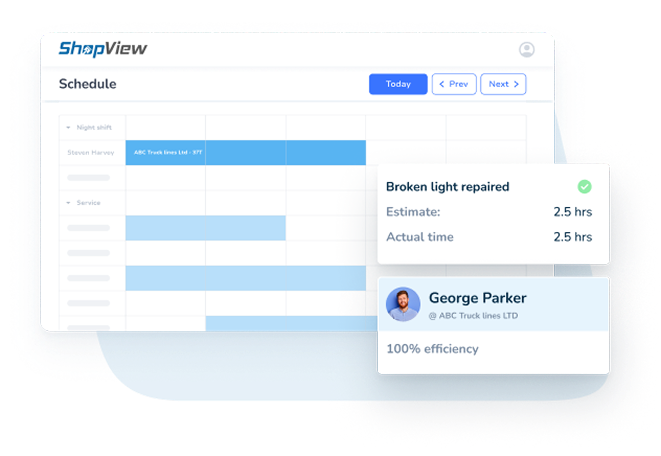

Technician Productivity

Track and improve technician efficiency.

Inventory Usage Insights

Optimize parts usage and reduce waste.

Built By Heavy Duty Shop Owners Who Know the Grind

Our team has 20+ years of collective experience in heavy-duty repair. We built ShopView to address the real challenges we faced running our own shops - from work order chaos to billing headaches to technician productivity.

"ShopView made our shops more productive and efficient - and it will do the same for yours."

See How ShopView Helps Heavy-Duty ShopsWhy Choose ShopView?

Available on All Devices

Simple to set up and use on computers, smartphones and tablets. Your data syncs across all devices in real-time.

Seamless Integration

Connects with accounting and business systems you already use, including QuickBooks, IBS, and more.

Comprehensive Support

From onboarding to ongoing support, reach out anytime for help. We guarantee a response within 12 hours.

Truck and Trailer Repair Shop Software: Keep Your Fleets Rolling

Why Fast Turnaround Matters

When a semi-tractor or trailer sits idle rather than generating revenue, all stakeholders lose money. Industry sources indicate that unplanned downtime can cost fleets between $448-$760 per day in lost revenue and ancillary expenses.

For independent repair shops, while these costs don't appear directly on your balance sheet, they affect customer satisfaction and loyalty. Fast turnaround times matter because they minimize customer losses and strengthen your competitive position.

Turnaround involves more than physical repair speed - it encompasses capturing billable labor accurately, managing parts inventory efficiently, obtaining approvals without delays, and processing invoices promptly.

What Does Truck and Trailer Repair Software Do?

Purpose-built truck repair software consolidates all operational elements into a single platform. Unlike generic systems, it allows you to:

- Create one work order encompassing a tractor, trailer, and auxiliary equipment simultaneously

- Track which technician completed which task, parts consumed, and labor duration

- Manage VIN decoding for commercial vehicles, core part tracking, DOT inspection scheduling

- Integrate parts inventory across shop locations and mobile service units

- Convert approved estimates to invoices without re-entry

- Sync directly with accounting software like QuickBooks

- Enable field technicians to access work orders even without internet connectivity

Top Challenges in Truck Shops

Labour Capture - Without task-based time tracking, minutes blur together, losing approximately 1.5 hours per technician daily.

Parts Complexity - Day cabs, sleepers, reefers, flatbeds, tankers all require different components.

Resource Balancing - Juggling scheduled maintenance, DOT inspections, emergency repairs and road calls.

Regulatory Compliance - DOT standards, driver vehicle inspection reports and emissions controls demand meticulous documentation.

Invoice Accuracy - Data hand-entered multiple times leads to billing errors and disputes.

Features That Make a Difference

- Rapid Multi-Asset Work Orders - Build orders with tractors, trailers and auxiliary equipment on one ticket within seconds

- Integrated Time Tracking - Assigns labor precisely to each component, feeding into invoicing and payroll

- Digital Parts Inventory - Tracks stock across locations with automatic reorder triggers

- Visual Scheduling - Drag-and-drop assignment of jobs to bays and technicians

- VIN Decoding - Pulls vehicle specifications automatically with AI-powered labor guides

- One-Click Estimate-to-Invoice - Eliminates re-entry and errors

- QuickBooks Integration - Posts transactions directly to accounting

- Mobile Apps - Offline access with automatic sync when connectivity returns

Why Now: Trends Driving Digital Adoption

Increased Freight Demand - E-commerce has increased demand, with trucks operating longer due to supply chain constraints.

Rising Labor Rates - Approximately $134/hour industry-wide, with 44% of shops raising rates multiple times yearly.

Technician Shortage - Modern tools make shops more attractive to prospective hires.

Fleet Technology Adoption - Increased 23% year-over-year, with fleet management revenues projected to quadruple by 2032.

Tightening Regulations - Environmental rules create compliance documentation burdens that digital systems handle efficiently.

Customer Expectations - Fleets increasingly select service partners demonstrating technological capability.

Benefits: Less Downtime, More Billables

- Faster Repairs - Real-time scheduling and parts availability reduce repair cycles

- Proactive Maintenance - PM and DOT inspections help customers avoid downtime ($760+/day)

- Recovered Labor - Task-based tracking recovers ~1.5 billable hours per technician daily

- Inventory Control - Prevents duplicate orders and emergency purchases

- Faster Payments - Same-day billing and faster cash collection

- Compliance Ready - Digital records ensure audit transparency

- Better Morale - Technicians appreciate reduced paperwork; managers gain real-time visibility

Case Studies and Testimonials

Real-world implementations show tangible results:

- Multi-location heavy-duty repair businesses report achieving 100% technician productivity, saving over ten hours weekly at service desks, and adding approximately $15,000 in monthly revenue

- Other operations credit digital work orders and time tracking with reducing billing errors and freeing staff for revenue-generating tasks

- The Fleet Technology Index confirms small fleets increased technology adoption scores 23% in 2025

Fleet management software revenues are projected to grow from $27.55B (2024) to $116.56B (2032) - a 19.76% CAGR - demonstrating industry-wide acceptance.

How to Choose the Right Truck Software

- Industry Focus - Handles multi-asset work orders and includes parts kits for brake/suspension systems

- Ease of Use - Intuitive interfaces minimizing data entry

- Comprehensive Modules - Work orders, time tracking, inventory, scheduling, estimating, invoicing, reporting, compliance, customer communication

- Mobile Support - Offline field service access

- Integrations - QuickBooks, parts suppliers, VIN decoders, diagnostic platforms

- Pricing Transparency - No hidden fees for users, features or upgrades

- Scalability and Support - Implementation support, training, responsive assistance

Implementation and Best Practices

- Document Current Workflow - Establish baseline metrics and identify efficiency gaps

- Test-Drive Options - Use real scenarios involving tractor-trailer combinations and road calls

- Clean Your Data - Fix duplicates and missing information before import

- Run a Pilot - One bay or technician, maintaining backup processes for 1-2 weeks

- Bite-Sized Training - Focus on specific tasks with quick reference guides

- Gradual Rollout - Add technicians and modules once pilot runs smoothly

- Review Metrics - Unbilled hours, parts margins, invoice turnaround

- Designate a Champion - In-house expert to answer questions and train new hires

- Communicate Changes - Explain digital estimate delivery and approval processes to customers

- Calculate ROI - Compare labor hours billed, inventory turns, DSO to baseline

Conclusion: Keep Your Fleets Rolling

Out-of-service trucks and trailers cost fleets hundreds of dollars daily. Relying on clipboards, spreadsheets, or generic passenger-vehicle software exacerbates these losses.

Purpose-built truck and trailer repair software captures every labor hour, tracks every part, and manages every approval, enabling faster job completion and accurate billing.

Shops adopting these systems consistently report recovered labor time, reduced inventory chaos, and improved financial performance. With fleet maintenance software markets expanding rapidly and fleets embracing technology adoption, implementing capable software represents essential business strategy.

Your customers depend on you maintaining vehicle uptime. The right software keeps bays full, technicians satisfied, and invoices flowing, supporting sustainable growth and competitive advantage.

Ready to Increase Your Shop's Revenue by 20%+?

Join thousands of heavy-duty repair shops that trust ShopView to manage their operations profitably.